Transition Metal scales microbe tech for copper recovery

Say bacteria, most people think infection. Or yogurts. But a San Francisco-based startup is using microbes to get at something the world is hungry for: copper.

Transition Biomining, now rebranded as Transition Metal Solutions, has raised an oversubscribed $6 million seed round to scale a chemical approach that activates native microbes to lift copper yields from low-grade sulfide ores without changing mine infrastructure.

The company’s technology enhances the activity of microbes already present in mined ore, allowing operators to extract more copper while avoiding added biological systems or complex changes to heap leach operations. The round was led by Transition Ventures, with participation from climate and deeptech investors across the US, Europe and Australia.

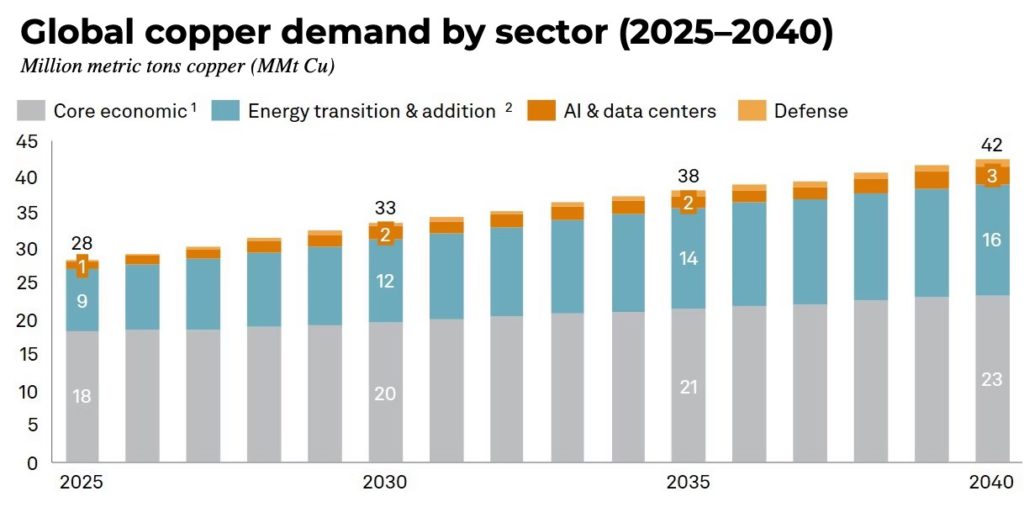

The financing comes as copper demand accelerates with electrification, renewable energy, electric vehicles and data centre buildouts, while supply growth lags. Copper was recently added to the US Critical Minerals List, underscoring its importance to economic and national security. Global demand is forecast to rise about 50% by 2040, even as higher-grade deposits are largely depleted.

What’s different

The company’s roots trace to work at a major copper mine where some heaps consistently outperformed expectations. The insight was not that microbes could unlock more copper. The industry has known that for decades and has repeatedly demonstrated it in the lab. The problem, according to founder and chief executive Sasha Milshteyn, is that those results rarely translate to real heaps at scale.

“What I saw at that copper project were all the reasons biology, as it’s been practiced in the industry, hasn’t produced consistent results,” Milshteyn told MINING.COM. “Most biomining research starts in shake flasks with cultured microbes, but those conditions are completely irrelevant to a heap.”

Heap leach environments are extreme: acidic, heterogeneous, and constantly changing. Traditional approaches focus on the small fraction of microbes that can be grown in bioreactors, but Milshteyn said that misses the point. In real heaps, the best-performing systems were driven by diverse microbial communities working together, most of which are unculturable. By some estimates, more than 99% of microbes in a heap will never grow in a lab.

Rather than introducing new organisms, Transition Metal Solutions focuses on working with biology that is already there. The company uses a proprietary platform to analyze microbial communities within a given orebody, then designs a site-specific chemical additive that shifts conditions inside the heap to favor microbes that drive sulfide oxidation, iron cycling and metal solubilization.

Crucially, the product the mine receives is chemical, not biological. Operators add it directly to the leaching solution using existing irrigation systems. No bioreactors. No inoculation facilities. No changes to the flowsheet.

That distinction has major economic implications. Adding engineered or lab-adapted microbes typically requires site-specific infrastructure, permitting and operational expertise. During customer discovery, one mining project told the company it had budgeted roughly $20 million just for inoculation infrastructure. On top of that come energy costs, feedstock costs, and the operational risk of running a parallel biological system.

“Our approach flips that,” Milshteyn said. “We do a lot of analytical work up front, but when it comes to implementation, there’s no new infrastructure and no regulatory burden associated with introducing microbes. We’re just helping the microbes that are already there thrive.”

From lab to market

In lab tests on low-grade primary sulfide ore, the approach increased copper recovery to about 90% from roughly 60%. In more challenging mineralogy, including refractory, high-carbonate ore, the system delivered in situ acid generation and metal leaching at roughly three times typical industry rates. Inside the heap, the additives help maintain a healthier microbial ecosystem, shifting community composition toward populations that favor oxidation reactions and sustained acid production under harsh conditions.

Despite those results, skepticism remains. Many miners have seen biomining fail before. According to Milshteyn, the initial hurdle is convincing operators that this is not another version of past inoculation strategies.

“Once they understand the concept, the reaction is usually, ‘this makes a lot of sense,’” he said. “The bigger issue isn’t disbelief, it’s risk aversion. People want to see someone else prove it first.”

Founded in 2023, the company is based at UC Berkeley’s Bakar Labs for Energy & Materials and led by a team with backgrounds in metagenomics, mining and metallurgy. Chief operating officer and co-founder Alexandra Shiluk said the platform was shaped by extensive conversations with miners frustrated by earlier biomining efforts, and intentionally designed to remove adoption barriers.

Seed funding will support the transition from lab work to industrial-scale validation, including three-metre column pilots planned for the first half of 2026. Those trials will need to demonstrate not just higher recoveries, but consistent performance, controllability and compatibility with existing operations.

The rebrand to Transition Metal Solutions reflects both timing and positioning. Copper demand is surging, driven by the energy transition and AI-related infrastructure, while recoveries from sulfide ores remain low, often below 60%. These ores make up roughly 80% of remaining copper reserves. Without a scalable way to leach sulfides economically, the industry cannot meet future demand.

At the same time, the company has deliberately moved away from being perceived as a “bio” startup. While microbes are central to the mechanism, the product mines deploy is chemical, and the value proposition is operational simplicity.

If the technology scales as expected, the implications could be significant. The approach could unlock tens of millions of tonnes of copper currently sitting in stockpiles of already-mined but uneconomic ore, extend the life of existing heap leach operations by enabling re-leaching of spent heaps, and increase overall productivity without major capital investment. More complete sulfide oxidation could also reduce long-term acid mine drainage risk in spent ore.

While copper is the initial focus, the platform applies to any sulfide-hosted metal, including nickel, cobalt, zinc, silver and gold. In a world facing structural shortages of critical metals, the company’s bet is that the fastest gains won’t come from new mines, but from getting more out of the material that’s already been dug up.

More News

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments