Niron breaks ground on rare earth-free magnet manufacturing plant in Minnesota

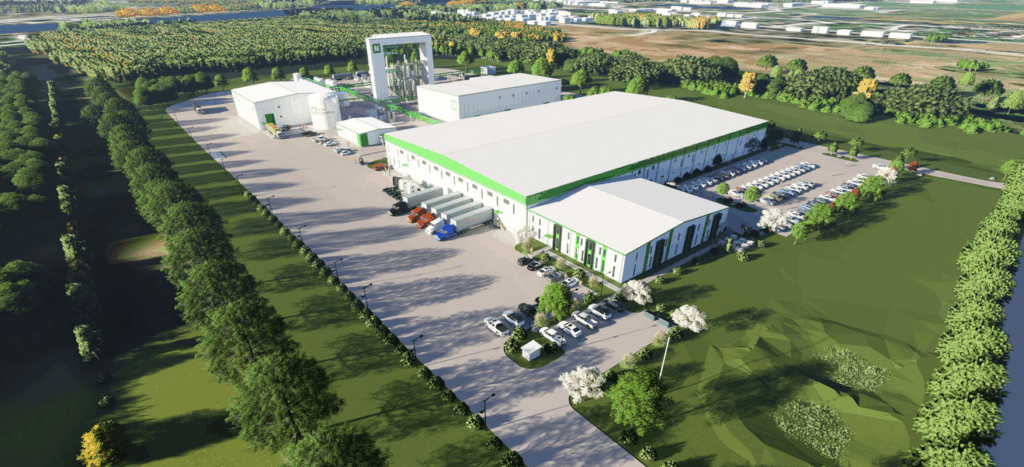

Niron Magnetics broke ground Friday on a new 1,500-ton-per-year permanent magnet manufacturing facility in Sartell, Minnesota.

After nearly a decade of research and development in partnership with the US Department of Energy (DOE) and the University of Minnesota, Niron said it has successfully created one of the first commercially viable new magnet materials in decades, capable of producing superior permanent magnets.

Privately-held Niron said its product does not contain any rare earth elements, and are made from abundant elements such as iron and nitrogen.

The company highlighted that it is able to scale manufacturing of permanent magnets made from iron nitride, which exhibits exceptionally high magnetization and removes the need for rare earth elements.

Investors and commercial partners including Stellantis, Samsung, Allison Transmission, Magna and others are already sampling products from the company’s pilot facility, it said.

The new 190,000-square-foot facility will expand Niron’s capacity to supply rare-earth-free permanent magnets for data center cooling pumps, automobile motors, robotics, consumer electronics, defense and drone equipment, and other applications critical to the US economy.

The facility will be built on the former Verso Paper Mill site, redeveloping a US designated coal community property.

The development comes at a critical time, as pressure on rare earth supply chains intensifies due to geopolitical tensions and rising demand for permanent magnets globally.

“We’re proud to scale this homegrown technology in the heart of the industrial Midwest, and excited to make this community central to America’s supply chain independence,” Niron CEO Jonathan Rowntree said in a news release.

The plant will be operational in early 2027 and will create over 175 full-time jobs in manufacturing, engineering and operations, the company said.

“Permanent magnets are an essential part of modern vehicles, the heart of the performance for everything from powertrains and cooling systems to seat motors and speakers. We are committed to offering the freedom of choice to our customers and the integration of these magnets is critical to that mission,” said Sinisa Jurkovic, Stellantis VP, propulsion systems engineering.

“We’ve been working with Niron since 2023 to unlock next-generation motor performance, and iron nitride technology is helping us engineer and deliver vehicles with best-in-class capabilities.”

More News

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

5 Comments

Mediacritic

I have been reading this development and am pleased with new technology we either can use less rare earth’s in products ir none at all. Those still needed being increasingly sourced from no Chinese sources eg Australia where a value chain has been established and will grow as it is the largest non chinese source of rare earth’s.

Allan Hochman

please advi as to whether or not the company is a publicly traded entity and if so please supply the trading details.. If not publicly traded, please advise your intent as to when you anticipate this occurring.

Jackson Chen

Hi, the company is privately held.

William

Is an iron Magnetics going to be listed on the ASX?

Regards

William

Alex

Very big achievement tbh hope everything will work out perfectly