EnergyX enters US manufacturing phase

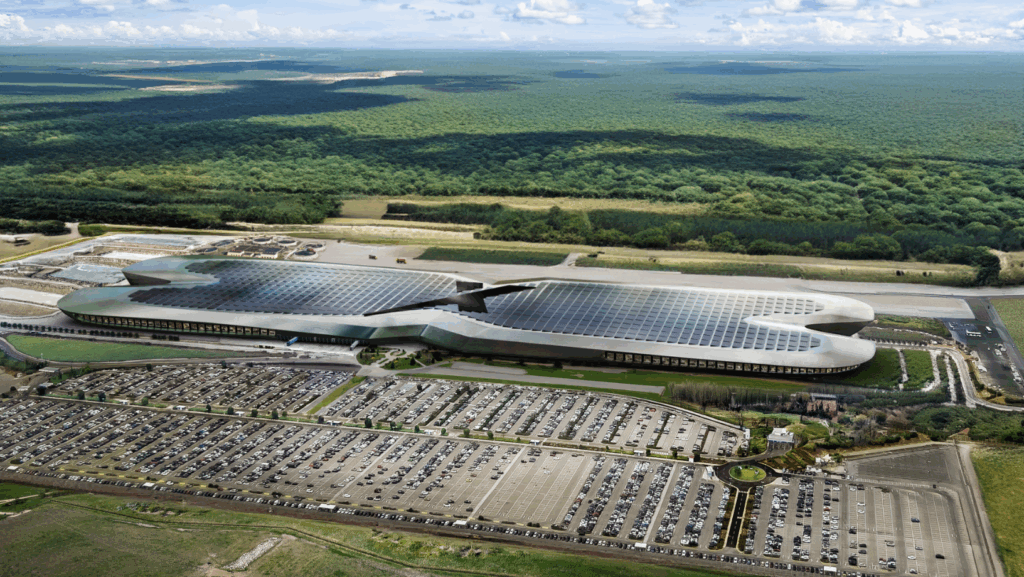

Energy Exploration Technologies (EnergyX) announced Wednesday that its advanced materials manufacturing is now operational with the commissioning of one of the largest roll-to-roll membrane production machines in North America at its Austin, Texas facility.

This brings critical process manufacturing onto American shores, strengthens the underlying technology needed for domestic lithium supply, and establishes a scalable platform serving alternative high-growth clean energy markets including desalination, carbon capture, and advanced industrial manufacturing, the company said.

With the facility now live, EnergyX can internally produce a core component of its GET-Lit lithium separation technology portfolio at industrial scale. Producing up to 500,000 square meters of ion exchange membranes per year, this in-house capability reduces EnergyX’s reliance on overseas suppliers and production lead times.

In January, EnergyX entered the nuclear materials sector, positioning the company as a future domestic supplier of critical lithium isotopes required for both fusion and fission reactors.

That came a year after it acquired Daytona Lithium, which owns mineral rights in southwest Arkansas, where it is progressing its Lonestar lithium project.

“Our vision at EnergyX is to vertically integrate as much of our critical supply chain as possible,” EnergyX CEO Teague Egan said in a news release.

“We need to control the production of the actual consumables that enable our breakthrough lithium extraction and recovery process. It’s also very convenient that these proprietary membranes are applicable and extremely sought after in the carbon capture and other rapidly growing markets.”

Deliveries of its first commercial membrane and equipment sales are expected in Q1 2026, the company said, adding that the ion exchange membrane and electrodialysis systems market represent a projected $7.5B by 2035.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments