Crushing your sustainability goals – one stone at a time

Mines around the world are confronted with a dilemma. As the global demand for minerals and metals increases, so does the environmental challenge posed by needing to process more ore, on the heels of a greater need for energy efficiency.

The reality is that the world needs minerals as it accelerates towards electrification and a more sustainable future. Finding the balance between production, profitability and sustainability is key to ensuring that a more sustainable future is also a profitable one. This article explores how sustainable plant improvements in crushing and screening can translate into productivity, cost savings and profitability.

Careful selection of crusher spares and wears

Next to choosing the right crusher for your site and application, the right wear and spare parts come in a close second place. For example, when it comes to wear liners, a common practice is for site managers to continue with the same type of liner that originally came with their crusher. However, choosing a more optimal liner can have a big impact on performance, sustainability, uptime, change-out risk reduction and overall production costs.

Some considerations for liner selection includes cavity profiles, thickness and alloy grade. Base offering liners, often made of low-grade manganese steel, are suitable for the initial commissioning stage. Improved manganese grades, alloy steel or high-chrome white iron alloys are ways to maximize wear life and increase fatigue resistance, as is relevant to the operation.

Less waste with long-life crusher parts

Reducing downtime is essential for profitability and reaching production targets. Long-life wear crusher parts provide longer change-out windows, which in turn, reduces the need for maintenance activities. This limits the frequency of risk exposure, increasing safety. It can also mean less consumption of liners, which can save tangibly on costs. It also plays a big role in sustainability. For example, the environmental benefit of this can be seen throughout the supply chain, including less raw materials used, less production and reduced transportation or logistics.

Enhancing the lifetime of wear parts comes from selecting high-wear alloys that are best suited for your application. Further analysis through an optimization program can include recommendations of new alloys or even more tailored chamber optimization options. Designing your liners specifically for your application and ore can also mean an optimum wear life that goes hand in hand with your crusher running smoothly, within the original design parameters, meaning fewer breakdowns and unplanned downtime.

A similar situation is seen for other components such as crushers heads. For softer ores, lighter duty heads may be more than sufficient. However, for more demanding applications, either a Heavy-duty head or Forged head may provide significantly more component life and allow the crushers to be pushed to their limit while reducing waste.

During manufacture, Heavy duty casted heads have the head cavity machined, which removes stress risers which can be inherent in the casting. This prevents stress fractures from occurring at those points and leads to longer life heads. For the most demanding applications, a Forged head, created from a single forged ingot, provides the most durable option. Fully forged and machined, this head was designed to handle the needs of the most demanding and abrasive ores. Selecting the right head can significantly cut down the costs of purchasing new components and helps to reduce waste sent to the landfill.

Liner optimization: There’s always potential for improvement

By working together to carefully analyze your specific operating conditions, liners can be optimized to ensure an efficient and more sustainable process. Optimization can also have a direct impact on energy consumption and recirculation loads.

A partnership with a chamber optimization program can identify mutually agreed targets and find areas where there is potential for improvement. As the feed ores change over time, an optimization program can ensure that your liners adapt, and you don’t get caught using a design that is no longer as effective or performing.

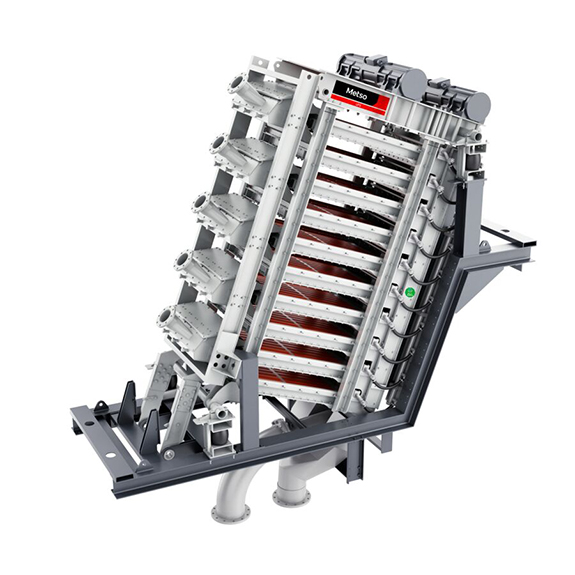

Screening the options for higher sustainability

Improving sustainability in screening can be done in several different ways. When acquiring new screening equipment, there are options with clear sustainability benefits such as reduced energy consumption, lower circulating load and overall improvements in the downstream processes. It is also possible to design a screening process that does not need water or tailings dams.

Like choosing crusher liners, it is a good idea to not just go for the same replacement screen model without looking into other options. Many popular screen models have alternatives with the same footprint, same feed and discharge chute locations, but also with clear sustainability benefits. If you want to improve the sustainability of your existing screening process, you first need to make sure that your screen is running in an optimal way – i.e. not causing unnecessary wear on equipment and parts which can lead to additional waste being generated. One way to verify is through having an expert test, measure and analyze the dynamic performance of your vibratory screens. It is also possible to install monitoring equipment onto the screen to keep track of its health, and thereby support maintenance planning and reduce unplanned downtime. Problems caught early often mean less components needing to be changed out or repaired, resulting in less wastage.

From media to refurbishments, making a green impact

A second topic to take a closer look at is the screening media. In mining operations with fixed maintenance stops, the media must perform until the next scheduled stoppage. Overperforming media, i.e. media that lasts almost until the next maintenance stop, is not more valuable to the operation than a media which lasts until the stop. All the media which will not last until the next stop is changed anyway.

Finding a supplier who can offer the widest end-to-end range of solutions makes it possible to select exactly the right type of media for your screen. Analyzing your screening process, application, and targets can guide you in selecting the right media for the application to improve sustainability.

A few examples of improvement opportunities could be changing from steel media to rubber media, which can have a large impact on reducing CO2 emissions. Working with modular screen media can also help trim down the need to change out an entire screen face. Modular media allows a site to only change out the worn-out panels, which results in less waste and in many cases reduced costs as only a small surface area of the screen would need to have the media changed.

There are also many sustainable possibilities through refurbishing parts instead of merely buying new ones. Trade-in programs, such as Metso MV (modular vibrator) Exchange Program can be a sustainable choice. By refurbishing, instead of throwing the used MV exciter away, less waste is produced at the same time significantly reducing costs and downtime.

Bringing it all together

Finding a trusted partner who can work with you towards your sustainability and profitability goals can make all the difference. There can be many opportunities hiding in plain sight when the crushing and screening part of the process is looked at in closer detail.

Once a plant has mapped out how their crushing and screening is performing, the information can be used to highlight options that could make the biggest impact. One thing that can be counted on is that whatever the challenge, a true partner can help a site move closer to both its sustainability as well as performance goals.

For more ideas and inspiration, explore Metso’s full aftermarket offering here: Your #1 service partner from pit to port

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments