For sustainability gains – look to your liners!

Increasing demand for metals and minerals, coupled with declining ore grades, means that mines must process ever larger amounts of ore to produce the same amount of product. However, processing more materials carries a price.

Higher energy consumption is often required, with both environmental and financial implications, especially in view of rising global energy prices. Mining industry statistics indicate that the entire mining industry consumes approximately 3.5% of total final energy consumption globally. Comminution (crushing and grinding) within that industry may account for up to 1% of that total, as per the CEEC International: Coalition for Minerals Efficiency

The additional processing needed to maintain production levels also leads to an increase in premature wear and tear on both equipment as well as wear and spare parts, resulting in excessive quantities of material sent to landfills. Replacing worn units with new machines and components also comes with a high carbon footprint, tied to the manufacturing process and fuel used in transport to site.

Facing the challenges of reducing energy usage as well as minimizing waste, miners are looking at diverse ways to optimize energy consumption throughout the mining process and to get more life from their parts.

However, it is not always so easy to make a start. One approach is to first look at the crushing process within the comminution stage. Modifications or improvements made at the primary or secondary crushing steps can have an immediate impact on sustainability and may also lead to gains further downstream.

Unlocking the potential with crusher wear parts

When looking into the crushing circuit, wear parts offer a great opportunity to make a sustainable impact. Choosing crusher wear parts that extend the wear life can provide multiple benefits to your crusher, while also supporting sustainability targets.

Maximizing the lifetime of crusher wear parts results in less waste that needs to be managed and recycled. Fewer parts also need to be supplied, so sustainability benefits are seen throughout the supply chain from less production needed to CO2 savings from reduced foundry operations and transport of replacement wear parts.

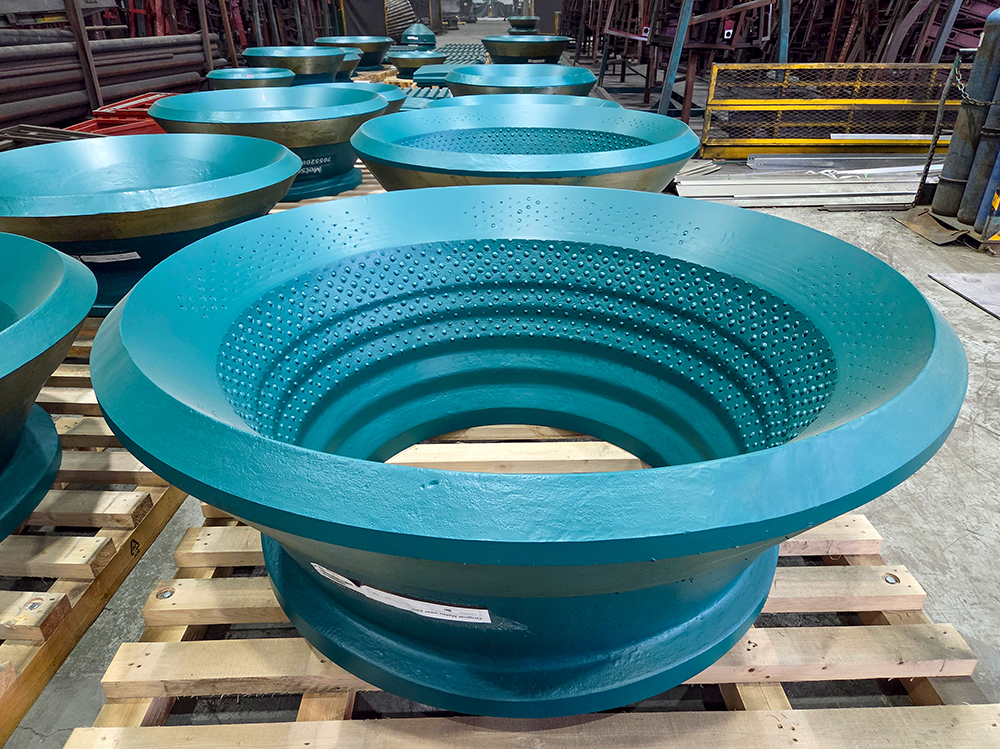

As an example of more sustainable wear parts, Metso MX for cones can offer up to double the wear life in secondary cone crushing applications. This results in calculable and tangible sustainability benefits – half the wear parts needed, half the liner backings as waste, reduced manufacturing inputs such as water, energy and sand mold, and less transportation emissions.

What’s more, all maintenance activities require a great deal from site staff – they are time-intensive in terms of planning and implementation, require highly experienced personnel and have inherent risk exposure. Fewer change-outs mean a reduced need for all the activities linked to maintenance breaks and higher productive time for your crushers, which can impact profitability. High-risk activities can also be minimized with less frequent changeouts.

Maximizing crushing performance with wear optimization

The performance of a crusher is directly related to two key factors: first, the properties of the rock or ore being crushed, which include crushability, abrasiveness and humidity. The second key factor is the crusher cavity, which plays a vital role in the crushing performance. The throughput volume, output gradation, energy consumption and the wear life of the cavities are some of the performance indicators that need to be monitored.

Because every crushing application is different, there is potential for improvement by customizing the design of the crusher’s wear parts. If the crushing chamber is not functioning optimally, it can result in negative consequences such as mechanical issues, high-power usage, low capacity and non-optimal product sizing.

Metso Chamber Optimization service takes a deep dive into identifying places in the crushing process for improvements. Metso engineers can help select optimal alloys and address bottlenecks in the process, designing wear parts perfectly suited to your application and requirements. These together can help contribute to wear life improvements, annual downtime reduction for spares and wears replacements and sustainability benefits. Potential improvements to crusher efficiency through optimization can result in up to a 30% reduction in energy consumption.

Chamber Optimization of crusher wear parts can also support an improved plant balance, reducing overall OPEX. Although crushing is an energy-intensive process, milling is often the largest energy consuming stage within the circuit. Improving crusher performance through Chamber Optimization can result in a finer and more optimal product feed being sent to the mill. This can lead to increased mill throughput and an overall energy reduction of up to 15% in downstream milling, while also increasing grinding production.

Opportunities from optimization are not just a one-off activity. Rather, it can be a continuous, ongoing process with further gains possible for efficiency and sustainable operations. As ore properties evolve or production targets shift due to market fluctuations, it’s essential to adapt the selected wear parts and investigate further optimizing the crusher chamber in one or more crushing stages down the road.

Taking a wider view

Improvements made at the crushing process stage can be a quick way to score important sustainability gains and impact downstream processes. However, taking a wider view of your entire flowsheet is important and no stone should be left unturned when it comes to exploring ways to reduce waste and improve energy efficiency.

Carefully examining how your loading and hauling equipment, grinding mill, filters and flotation cells are performing can help identify further opportunities which can make a significant impact on your plant’s environmental performance. Whether it is optimizing the operating parameters of equipment, considering upgrades to less efficient equipment or parts, or even replacing older equipment with modern machines with the latest technology, each improvement can be a step towards realizing your targets on the journey to Net zero.

For more ideas and inspiration, explore Metso’s full aftermarket offering here: Your #1 service partner from pit to port.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments