Gearing up for reliable mill performance

Minerals processing plant operators recognize the complex challenge of maintaining and operating grinding circuit equipment and components. Grinding mills are massive machines subject to intense wear and tear, shifting production demands, and aging components — all of which can complicate maintenance planning. From liners and lubrication systems to drive components and digital monitoring tools, each element plays a role in keeping the mill running efficiently and smoothly. Overlooking even minor issues can lead to costly downtime.

Driving toward outcomes

Grinding mill maintenance is often a reactive practice initiated by component failure and subsequent equipment breakdown. Unplanned machine shutdowns lead to significant production losses and increased operating costs from the vital resources required to get the grinding mill back in operating condition as quickly as possible. For plant operators the goal is clear: maximize machine uptime and equipment reliability. Achieving this requires a proactive approach to maintenance that goes beyond reactive repairs. With production targets constantly evolving, mining companies are increasingly focused on strategies that extend equipment life, reduce unplanned shutdowns, and ensure consistent performance.

Smarter tools to stay ahead of the curve

Regular inspections are a first step toward proactive maintenance. By detecting problems early through recurring equipment assessments to ensure the machine and its components are in proper working order, operators can avoid major equipment issues and unplanned failures. While regular checkups help maintain mill availability, upgrading equipment with modern technology enables more proactive maintenance planning — reducing reactive responses and requiring less investment than purchasing new machinery.

Innovative maintenance practices help operators stay ahead of the curve by leveraging new digital tools and data capture methods. Technologies like pinion temperature monitoring and vibrational analysis are transforming how horizontal mills are maintained. These upgrades provide real-time insights into component health, allowing teams to detect issues early and plan interventions during scheduled shutdowns rather than reacting when issues arise.

Technologies such as pinion temperature monitoring help sites stay ahead of unplanned downtime

Liner wear monitoring has also captured the attention of plant operators, as changing liners too early can result in wasted part life and higher replacement costs, while waiting too long can result in part failure that can damage other areas of the mill. For stirred mills including Vertimill®, remote monitoring solutions such as VertiSense™ provide real-time liner wear tracking — enhancing profitability, efficiency, and sustainability. By replacing manual inspections with predictive diagnostics — and guesswork with hard data — operators can reduce maintenance costs, improve safety, and extend the life of critical assets.

Gearboxes – another piece of the puzzle

Managing all the components and parts of a horizontal or stirred mill can make maintenance teams feel like they are piecing together a puzzle. If one piece is not in place or underperforming due to age, the entire assembly can suffer. The grinding process is only as reliable as the technology that drives it. Regular equipment and component maintenance are critical to keep grinding mills operating at peak performance.

The mill’s drivetrain and gearbox are key components in the equipment reliability equation. The drivetrain is often referred to as the heart of the mill’s operation, and without proper design and maintenance, operators may risk reduced performance, increased maintenance and costly downtime. With many mills in operation for 20-30 years or more, older components may struggle to meet the production demands of modern mines.

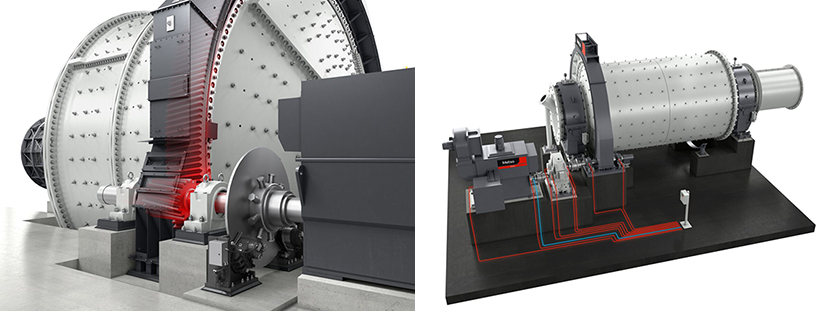

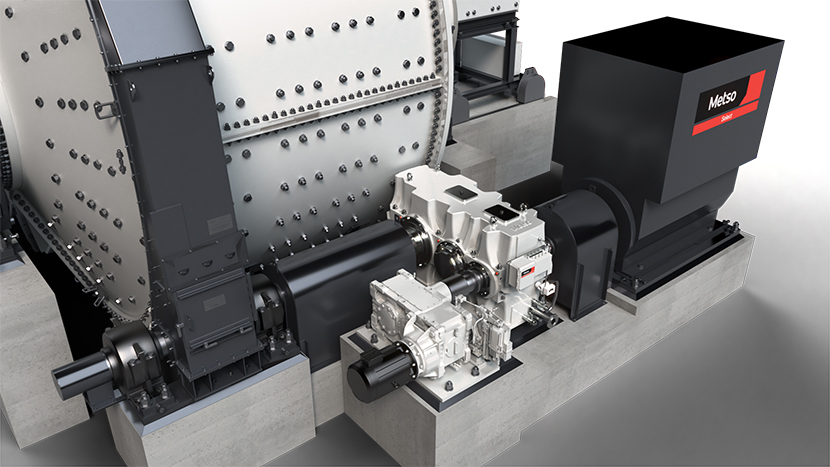

Caption: Metso Power Transmission (MPT) solutions for horizontal and vertical grinding mills are designed to offer exceptional reliability, serviceability, and OEM value in aftermarket applications.

While gearboxes are a standard feature across the industry, Metso has taken a significant step forward in grinding mill equipment reliability and performance with the launch of Metso Power Transmission (MPT). MPT is a proprietary line of gearboxes designed and manufactured to integrate seamlessly with Metso’s grinding mills, offering enhanced compatibility, durability, and performance. Available for both horizontal and vertical grinding mill applications, MPT gearboxes feature built-in condition monitoring systems that support predictive maintenance and can help operators avoid costly equipment failures and downtime. Featuring a modular design, optimized oil flow, and precision engineering, the gearboxes are built for smooth, stable operation and longer service life.

“Metso Power Transmission is the culmination of our extensive global grinding expertise,” states Kari Uusitalo, Metso VP, Gearbox and Drivetrain Technology. “The outcome is an extraordinarily robust and reliable gearbox and drivetrain solution that truly completes our end-to-end offering and delivers lasting value to our customers. By enhancing the components’ durability and design precision, Metso Power Transmission provides longer equipment service life and reduces overall maintenance requirements for improved operational efficiency, reduced downtime and increased production throughput.”

One partner, endless possibilities

Dealing with multiple suppliers of mill equipment, parts and services can be problematic and complex to manage. There are many benefits to working with a single supplier if they have a complete offer. One critical advantage is that a one-stop-shop supplier can have a full view of how the circuit is operated and maintained and a complete understanding of the real impact of any changes, such as an equipment upgrade or the addition of a new service element or program.

With the addition of MPT, Metso has strengthened its position as a comprehensive grinding solution provider. From spare parts and liners to upgrades, inspections, monitoring solutions, and expert services — Metso offers an end-to-end approach that simplifies maintenance planning and ensures system-wide compatibility. For plant operators, having a single source means easier coordination, faster support, and greater confidence in long-term grinding mill performance.

Explore Metso’s Power Train and gearbox offerings here – Power transmission – Metso

And discover the full range of grinding parts, upgrades and services – Grinding mill services – Metso

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments