Grinding & Crushing Optimization: Driving Continuous Improvement

Mill Liners Engineered for Efficiency and Longevity

Grinding mill liners are essential to achieving peak mill performance—and at ME Elecmetal, innovation drives every design. Our advanced liners and proprietary alloys are engineered to deliver proven wear life, reduce relining costs, and minimize downtime.

We collaborate closely with customers to perform detailed operational analyses, identifying the optimal liner configuration and materials for each specific application. Every liner is precisely engineered to maximize throughput, efficiency, and reliability.

With continuous wear monitoring and production tracking, we ensure ongoing performance optimization and the lowest total cost of ownership. Backed by stringent quality control and cutting-edge technology, ME Elecmetal’s liners provide the strength, durability, and confidence your operation demands.

ME PolyFIT® – Hybrid and Composite Liner Innovation

ME PolyFIT® liners are designed with abrasion-resistant rubber compounds and can be integrated seamlessly with ME Elecmetal’s steel liners. These hybrid solutions provide:

- Longer wear life and reduced downtime

- Optimized mill space utilization

- Fewer parts for quicker installation

This technology enables mining operations to boost efficiency and maximize uptime while maintaining robust performance under demanding conditions.

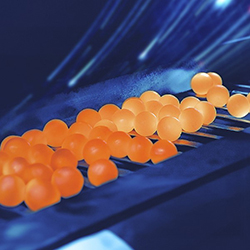

Grinding Media Solutions that Evolve with Your Operation

ME Elecmetal is a trusted global supplier of high-quality forged steel grinding media for SAG, ball, tower, and rod mills. Backed by decades of field experience and engineering expertise, we help customers drive continuous improvement in grinding performance across mining operations worldwide.

Our dedicated team of sales and application engineers collaborates closely with customers to:

- Analyze operational data

- Optimize grinding media consumption

- Refine charging practices

- Maximize throughput and mill efficiency

We ensure timely, reliable delivery and provide comprehensive support from product selection to on-site performance evaluation—ensuring consistent, high-impact results through every stage of the process.

With robust production capacity and a strong global presence, ME Elecmetal is more than a grinding media supplier—we are a strategic partner committed to helping customers achieve long-term operational success.

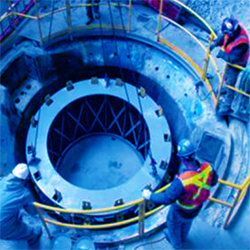

Crusher Wear Parts and Safety Tooling for Safer, Smarter Crushing

Crusher Wear Solutions – Our comprehensive range of crusher wear parts ME Elecmetal delivers high-performance alloys and engineered designs tailored to the specific demands of primary, secondary, and tertiary crushing applications. Our crusher wear solutions are built for reliability, durability, and easy integration, making us a trusted partner in crushing optimization.

Key Advantages:

Minimized Downtime: Quick and precise liner changeouts keep operations running smoothly and reduce maintenance-related delays.

- Seamless Compatibility: Products are designed to fit effortlessly with your on-site equipment, ensuring hassle-free replacement and long-term performance.

- Enhanced Equipment Life: Rugged materials and smart designs extend the lifespan of critical components, lowering total cost of ownership.

- Safety-First Approach: Our comprehensive line of Crusher Safety Tooling improves maintenance speed, reduces risk, and supports a safer work environment.

- Integrated Solutions: We don’t just sell products—we solve problems. Every solution is backed by our deep industry expertise and commitment to delivering real value.

With ME Elecmetal, you gain more than wear parts—you gain a partner dedicated to your operational success.

Safety Tooling – ME Elecmetal’s safety tooling products are purpose-built to simplify crusher maintenance and improve safety. Designed for ease of use and precision, these tools reduce human-machine interaction and support safer, faster maintenance processes across crushing operations.

Empowering Innovation with Advanced Optimization Tools

Digital Tools that Drive Data-Driven Decisions

Our advanced suite of optimization tools goes beyond conventional monitoring, enabling precise control, delivering critical insights and ensuring every decision is data-driven. However, our commitment goes beyond just delivering innovative tools—we work closely with our clients to provide expert guidance, continuous support, and tailored solutions that maximize equipment performance, reduce operational risks, and deliver sustainable success.

QuickScan™ Crusher – ME Elecmetal’s remote-controlled robotic scanning system for primary crushers delivers fast, accurate visuals without the need for manual cleaning—simplifying the scanning process, reducing personnel exposure, and increasing efficiency.

QuickScan™ Grinding – ME Elecmetal’s rapid mill scanning system completes full scans in just 15 minutes—eliminating the need for personnel to enter the mill. We also offer optimized liner change-out processes to minimize downtime.

3D Laser Scanning and Wear & Performance Tracking – Our 3D Laser Scanning service delivers precise wear mapping for mill liners, crusher liners, ladles, and more—supporting accurate reverse engineering and maintenance planning.

Combined with our digital wear tracking platform, clients can monitor wear history, receive expert recommendations, and make data-driven decisions.

- Quick turnaround: Preliminary reports in little as two hours, full reports in two days

- Expert service: Performed by trained professionals using advanced tools

- Reliable insights: Improve maintenance, extend component life, and reduce downtime

ME SecureFIT® – Revolutionizing Mill Fastening Systems

ME SecureFIT® External Bolting – This revolutionary fastening solution enhances safety and efficiency in mill maintenance. By using externally inserted bolts, it eliminates the need for personnel to enter the mill during installation—reducing human-machine interaction, minimizing downtime, and accelerating liner changeouts. The result: improved worker safety and increased mill productivity, all without compromising performance.

ME SecureFIT Smart Bolting System (SBS) – SBS takes bolting innovation further by integrating real-time bolt tension monitoring through sensorized technology. This enables:

- Predictive maintenance through real-time data

- Improved equipment integrity and operational safety

- Versatile application across ball mills, SAG mills, thickeners, and more

Supported by expert training and advisory services, SBS is setting new standards in safe and reliable mill fastening solutions.

ME FIT® Programs – Fully Integrated Technology for Operational Excellence

With over a century of expertise, ME Elecmetal delivers tailored optimization solutions through its ME FIT Grinding and ME FIT Crushing programs. These initiatives address the unique challenges of each mining operation with a core focus on helping customers achieve production goals and long-term operational efficiency.

ME FIT® Programs emphasize continuous improvement through close collaboration between our clients and ME Elecmetal’s multidisciplinary team. Our structured, systematic approach aligns with customer objectives to deliver measurable results and optimized outcomes.

Value-Added Philosophy (VAP)

Our VAP framework is more than a method—it’s a mindset. By focusing on long-term value, trust-based relationships, and holistic technical solutions, we help customers overcome complex operational challenges and unlock new levels of performance.

Sustainability and Global Reach

Commitment to Circular Economy

ME Elecmetal is committed to sustainable manufacturing, offering 100% recyclable cast liners and a hybrid recycling process for large and medium-sized components. Through strategic partnerships, we have developed technologies to recover scrap grinding balls and remanufacture critical equipment components, reinforcing our commitment to sustainability.

Global Support, Localized Service

With ten state-of-the-art metallurgical plants, and commercial presence in over 40 countries, ME Elecmetal ensures fast delivery, localized support, and consistent quality wherever you operate.

Partnering for Long-Term Success

At ME Elecmetal, our mission is clear: to partner with our customers in maximizing operational performance, minimizing risk, and driving sustainable success. Through innovation, engineering excellence, and customer collaboration, we continue to set new benchmarks in grinding and crushing optimization.

Connect with Us Today!

Explore how ME Elecmetal can enhance your grinding and crushing operations through integrated solutions, digital innovation, and sustainable practices.

📍 Visit us at: www.me-elecmetal.com

📞 Call: +1 480-730-7500

📅 Join us at Convención Internacional de Minería, November 19–22, 2025 — Booth #6111, Acapulco

🔗 https://usa.me-elecmetal.com/en-us/events/convencion-internacional-de-mineria-2025/

We look forward to connecting with you!

About ME Elecmetal

ME Elecmetal is a leading global supplier and strategic partner in the mineral processing, aggregate, construction, and recycling industries, renowned for its commitment to innovation and technology. Dedicated to delivering cutting-edge, sustainable solutions, ME Elecmetal consistently exceeds customer expectations worldwide.

With a comprehensive range of products and services—including grinding media, mill liners, crusher liners, and large specialty castings—ME Elecmetal is the preferred partner for crusher operators and mineral processors looking to optimize their operations.

The company operates ten state-of-the-art metallurgical plants strategically located across Chile, the USA, Peru, China, South Africa, Indonesia, and Zambia. With a robust manufacturing capacity exceeding 134,000 tons for foundry products and 600,000 tons for grinding media, the company continues to meet the growing demands of the mining industry.

ME Elecmetal’s commercial presence extends to over 40 countries, solidifying ME Elecmetal’s position as a global leader in delivering innovative solutions to critical sectors around the world.

Learn more about ME Elecmetal’s global footprint and commitment to excellence in integral solutions at www.me-elecmetal.com.

More News

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments