HPY Redefines Copper Recovery with Photon AI Technology

HPY Technology’s new-gen photon imaging now detects over 60% of the world’s copper ores once infeasible by sensor-based sorting.

In recent years, X-ray powered and AI-assisted sensor-based ore sorting has proven effective across many ore types, but its performance has been inconsistent for porphyry copper – known for low grades and high tonnage. As a global leader in sensor-based sorting, HPY Technology has independently developed a next-generation photon-counting X-ray imaging sensor, achieving a breakthrough in recovering over 60% of the world’s copper.

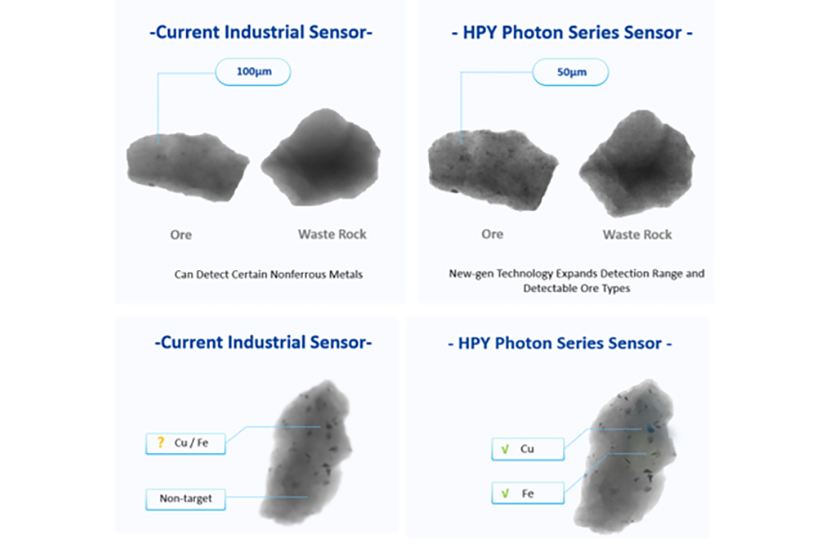

One of the major challenges in sorting copper ores, especiallyporphyry-type copper deposits, lies in distinguishing chalcopyrite from pyrite. These minerals often coexist in finely disseminated forms, with subtle differences in composition that traditional XRT sorting technology, even at 74-100-micron resolution, struggles to detect accurately. This overlap, combined with generally low grades, has long limited the effectiveness of sensor-based sorting in copper operations.

HPY’s new system addresses this gap with a photon-counting detector that dramatically enhances both spatial and material resolution. With imaging clarity down to 50 microns, the system can detect fine mineralized spots and distinguish chalcopyrite from pyrite based on their unique X-ray attenuation properties. By eliminating the scintillator layer used in traditional systems, the new sensor directly converts X-ray photons into electrical signals, reducing scatter, improving clarity, and enabling lower-dose, high-precision imaging. However, just like HPY’s past XRT system field application at the Comika Copper-Cobalt Mine in the DRC, the development of this Photon Sensor also reflects the company’s commitment to real-world performance – bridging lab innovation with field-proven results and paving the way for more adaptable and precise solutions.

Case Studies

One of Asia’s Largest Copper Porphyry Deposits – Jiangxi Copper’s Test Campaign

The impact of this new technology has already been demonstrated in real-world test campaigns. In cooperation with a Jiangxi Copper mine, one of largest open-pit copper porphyry deposits in Asia, HPY conducted a feasibility study on reclaiming copper from low-grade waste stockpiles. This copper mine has an estimated 3 billion tonnes of low-grade waste stockpiles, with average copper grades between 0.08% and 0.1%. HPY’s new sensor is able to effectively able to enrich the copper grade to twice its raw grade. The projected annual recovery from sorting 75 million tonnes of this waste material is between 24,000 and 30,000 tonnes of copper metal, representing a direct economic value of up to 330 million USD.

On a longer-term basis, with a conservative recovery rate of 40%, the potential copper recovery from the stockpiles could exceed one million tonnes, translating to over 13 billion USD in economic value – exclusive of additional metals such as molybdenum that may be recovered in downstream processing. This marks a transformative opportunity for mines to turn legacy waste into a viable source of high-value product.

| Raw Ore Grade | 0.08%-0.1% |

| Annual Processing Capacity | 75 million tonnes |

| Recovery Rate | 40% |

| Copper Stockpile’s Potential Value | 13 billion USD |

| Machine & Sensor Selection | 2 Classic Series with Photon Sensor |

Copper Sulphide Porphyry Deposits Test Campaign

Further proof of the new sensor’s capabilities came from another recent test with copper sulphide material. In Phase I of testing, using HPY’s previous-generation sensor, the system achieved up to 92.6% copper recovery, but could not reduce copper in the waste below 0.15% due to interference from iron sulphides.

In Phase II, using the new photon-counting sensor in theoretical modeling, waste rock grades could be reduced to below 0.08% while still maintaining 87.6% metal recovery at a 33% rejection rate. At a more aggressive 59% rejection rate, recovery remained strong at over 71%, with cleanly separated copper-bearing material. These results demonstrate the system’s ability to make sharper, more confident decisions even in complex sulphide ores—something that previous systems were unable to achieve.

| Test Items | Phase I | Phase II |

| Waste Rock Grade | 0.15% + | 0.08% – |

| Recovery Rate | 92.6% | 87.6% (At 33% rejection rate) 71% (At 59% rejection rate) |

Rising Demand, Shrinking Grades – From Waste to Wealth

As the global push for electrification, renewable energy, and advanced manufacturing accelerates, demand for critical metals – especially copper – is rising sharply. From electric vehicles and solar panels to power grids and data centers, copper plays an indispensable role in enabling the technologies of the future. Yet while demand continues to grow, easily accessible high-grade copper resources are in decline. This widening gap between supply and demand places increasing pressure on mining operations to extract more value from low-grade, finely disseminated, or previously uneconomic ore deposits.

In response to this industry-wide challenge, HPY Technology has developed a breakthrough solution. Leveraging years of research and testing in some of the world’s most complex copper deposits, HPY proudly introduces its next-generation copper sensor system, powered by photon-counting X-ray detection technology.

HPY’s Photon Sensor isn’t just a technological breakthrough – it’s a step forward for the industry. By enabling more precise separation of copper minerals from waste, it opens the door to higher recovery, lower energy, water, and chemical medium usage, and meaningful economic returns from materials once deemed uneconomic. As global electrification and infrastructure demands continue to grow, HPY is proud to support smarter, greener mining with solutions that meet the needs of tomorrow’s copper producers, today.

For more information or collaboration inquiries, please visit our website or contact us at [email protected].

More News

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments