Improve your milling production strategies & productivity goals

Grinding Solutions to Improve your Production Strategies and Productivity Goals

ME Elecmetal provides customized solutions according to the unique challenges and requirements of each mining operation to help our customers achieve their production strategies and productivity goals. We validate our performance through controls and measures to monitor our solution’s impact on our client’s key performance indicators: productivity, safety, efficiency and equipment availability and reliability.

Products and Services that Make an Impact

Mill Liners

Grinding mill liners are subjected to severe impact and high abrasion. They must be manufactured using the finest technologies and designs for exceptional strength and durability. That is why we make sure we offer customers the best possible solutions for every challenge and mill type.

ME Elecmetal analyzes customer operations to determine the ideal combination of design and materials to achieve optimal equipment performance. Whether it is an AG, SAG, ball, tower or rod mill, our innovative liner and alloy designs deliver proven performance, while minimizing expensive reline and downtime. We collaborate closely with operators and plant maintenance crews to monitor wear performance and production rates, customizing each liner for the best possible performance. All variables are considered in this analysis — from the characteristics of the ore and the customer’s operative strategies to their production targets. We identify opportunities for improvement and adapt to challenges as they arise to offer solutions that go beyond customer expectations.

Our mill liners are manufactured according to the highest quality standards and state-of-the-art technology and engineering, resulting in the most reliable, lowest total-cost-of-ownership-solutions for our customers.

Grinding Media

ME Elecmetal designs, manufactures, and supplies the highest quality forged steel grinding media for SAG and ball mills in the world. Our vast field experience, engineering and consulting expertise allows us to accurately analyze operational data, so we can support our customers in achieving continuous improvement in their grinding processes. The process begins when we deliver the grinding media to your site and ends when your final product exits the mill.

Our experience and large-scale grinding media production capacity have positioned ME Elecmetal as a strategic partner in the global mining market. Our experienced and knowledgeable sales and application engineers can help you monitor and improve your processes by collecting and analyzing operating data, improving media charging practices and offering solutions to optimize your grinding media consumption and improve throughput.

ME Elecmetal carries a wide range of ball products to suit customer grinding applications and operational requirements.

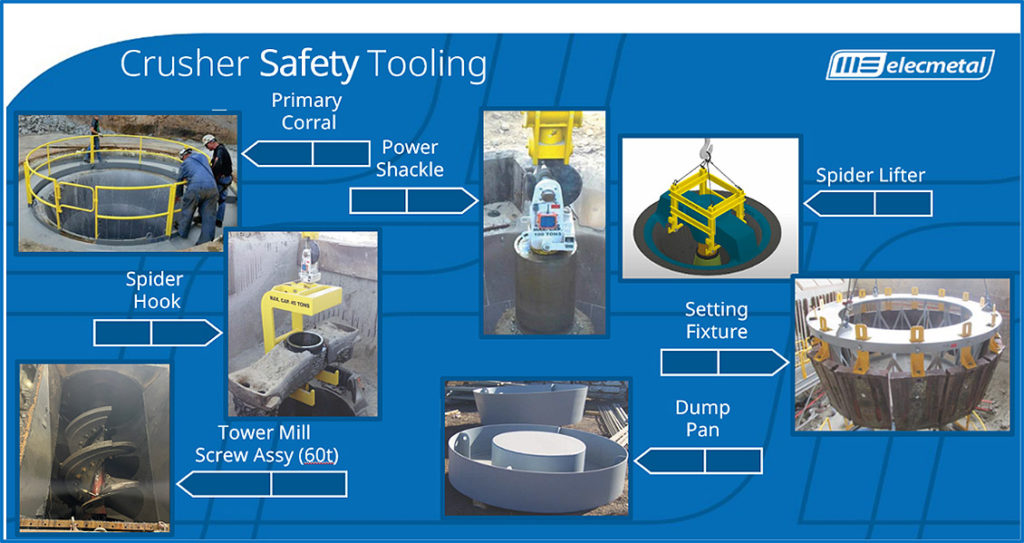

Crusher Wear Parts and Safety Tooling

ME Elecmetal is the leader in offering wear solutions to crusher operators. We provide crusher wear parts for primary, secondary, and tertiary crushing applications for the mining, aggregate and recycle industries with optimal designs and alloys specifically developed for each application. We will help confront any customer challenge, while striving to maximize the benefits we provide. We can adapt to any type of equipment customers may have on site.

With a focus on safety, durability, and ease-of-use, ME Elecmetal

also offers a full line of Crusher Safety Tooling products designed to help you get the job done safer, faster, and smarter! Our products include:

- Primary corrals

- Dump pans

- Setting fixtures

- Crusher nuts

- Power shackles

- Spider lifters

- Customized solutions

Innovation through Experience and Technical Knowledge

Optimization Tools and Services

There is an increasing demand in the mining industry for technology capable of optimizing processes, equipment, and performance. ME Elecmetal believes there is always room for improvement. We focus on delivering tailor-made technology solutions for grinding and crushing applications, with a complete offering of optimization tools, including wear monitoring, to further improve efficiency and provide our customers with timely information.

ME Elecmetal’s technical support and training goes beyond standard services offered by other suppliers. These services include DEM and FEM simulation services, 3D laser scanning for wear analysis, reline optimization, continuous improvement programs, grinding circuit optimization, and more.

ME FIT System®: Fully Integrated Technology

ME Elecmetal specializes in comprehensive solutions that make an impact on productivity in the global mining industry. Our two optimization programs – ME FIT Crushing and ME FIT Grinding – are built upon the foundations of a business philosophy backed by more than a century of experience of the mining industry. Through our ME FIT System programs, we design and deliver integrated solutions that add value to our customer’s mining processes. The programs focus on creating value for mining processes by quantifying the impact of their solutions, while improving key productivity indicators in mineral extraction and processing. Our ME FIT program solutions are made possible through mutual collaboration between our clients and the ME Elecmetal multidisciplinary team. By having an in-depth understanding of each mine site’s operational issues, we are able to positively impact priority key performance indicators: productivity, reliability, availability, safety, efficiency and / or energy consumption. We align with the priorities of our customers, positioning ME Elecmetal as a true strategic partner in mining.

Contact Us Today!

For more information on ME FIT System Solutions and to learn more about how ME Elecmetal can help you optimize your mining processes, visit www.me-elecmetal.com or call 480-730-7500.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments