Pumping up sustainability gains

As the mining industry faces increasing pressure to reduce its environmental footprint, mine sites and concentrator plants are turning to innovative strategies to conserve energy, water, and other critical resources. With sustainability becoming a central focus, operators are rethinking traditional processes and investing in technologies that not only improve efficiency but also align with global environmental standards. This shift reflects a broader commitment to responsible resource management and long-term operational resilience.

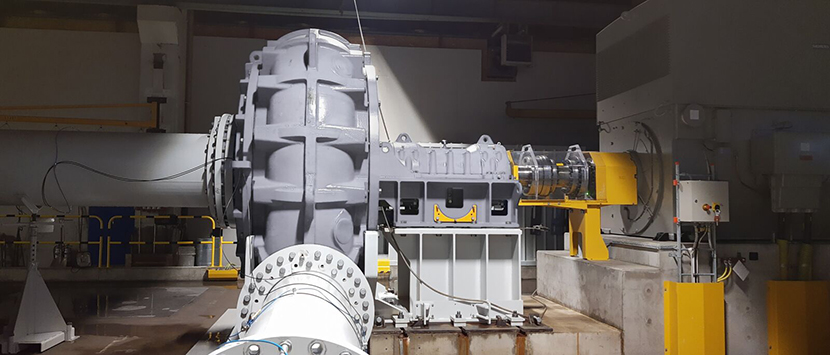

Many sites look first to equipment such as their grinding mills, primary crushers or ore sorting systems to explore ways to save energy. With water rapidly becoming a scarce resource, flotation cells, thickeners and tailings management strategies quickly come under the loop. But what about pumps? Installed at multiple points across a typical minerals processing facility, the way that a site or plant’s pumps are selected, sized, operated, and maintained can all play a major role in managing energy and water consumption. Getting these factors right can also help control the wear and tear on slurry pumps and reduce the amount of worn pump liners, components and valves consumed.

To save energy, choose the right pump

When it comes to efficiency and energy savings, many sites select equipment from different suppliers. This has the hazard of suppliers building in a safety factor on the sizing or selection of their individual equipment. If each supplier builds in this factor, it can result in significant oversizing across the circuit. For example, if a pump is oversized it may operate less efficiently and wear faster than an optimally sized pump. In extreme examples, a pump may not even be able to achieve the application if the details used to size the pump are dramatically different from what exists at the site.

Choosing the right pump not only improves hydraulic efficiency but also lowers operational costs. For example, Metso’s latest slurry pumps offer up to 17% higher efficiency, translating into around 15% less energy consumption. More efficient pumps also last longer, which means less frequent maintenance, fewer spare parts, and reduced carbon footprint across the value chain. Metso’s PumpDim software is utilized to size and select the best pump for an application.

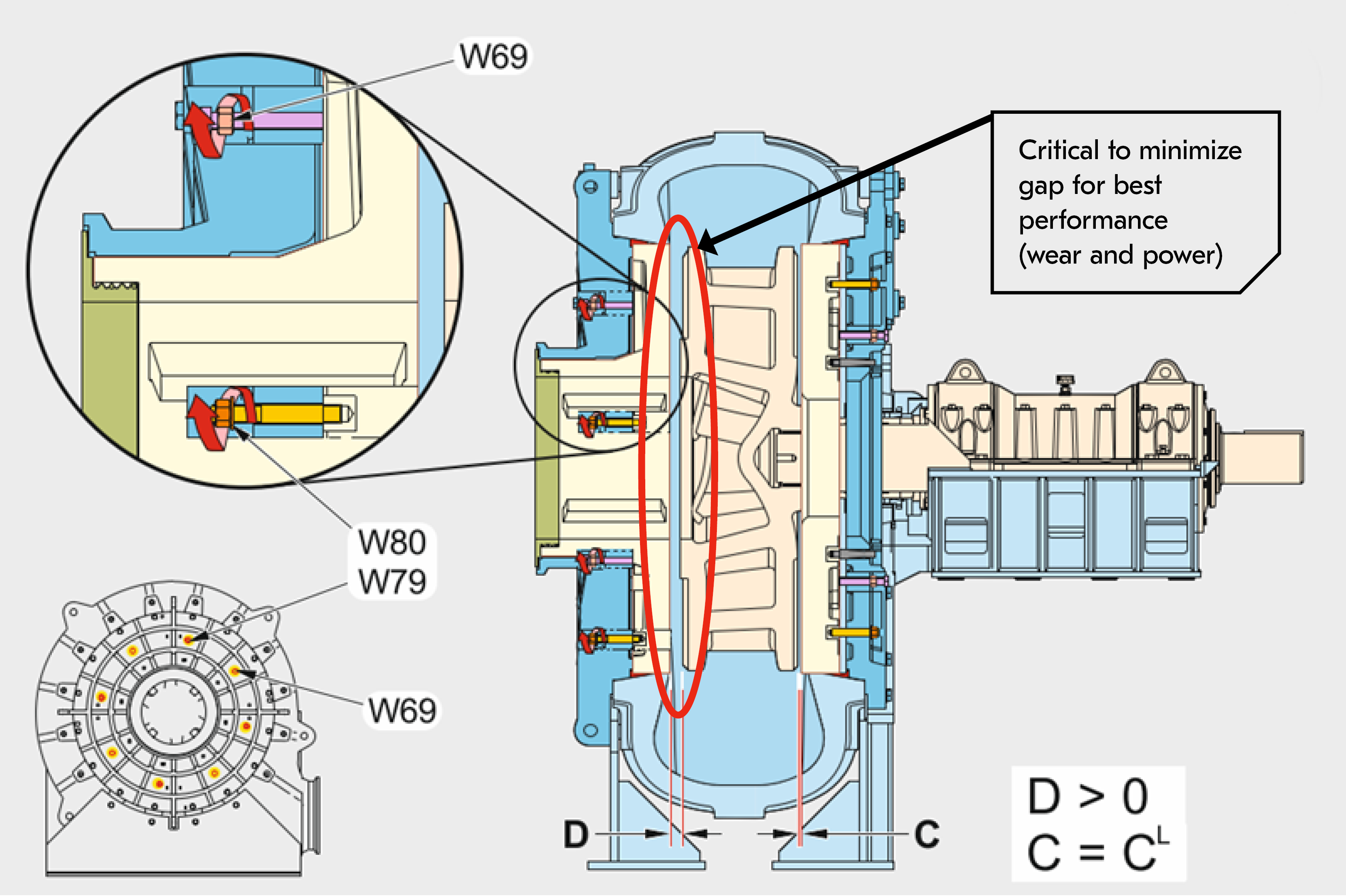

It doesn’t just stop once a pump is selected. Operator actions can also have an impact on energy use. Maintaining tight internal clearances by adjusting the gap between the impellor inlet liner to avoid recirculation can result in increased uptime and additional energy savings (See Figure 1). Another underestimated but crucial feature of slurry handling is pipeline configuration and wear monitoring. Aspects such as inner diameter, pipeline configuration, and lining material have significant implications not only in the pipeline wear resistance, but in process stability and energy consumption.

When every drop counts – water saving strategies

Water is increasingly scarce and costly at mine sites, and pumps, seals, and piping are critical to minimizing waste. Here again, choosing the right pump for the application can make a difference. For example, Metso’s MD pumps can reduce water consumption by up to 50% in specific applications. Within the MD pump series, technologies like EnviroSet™ seals cut sealing water demand while preventing leakage and contamination. Regular adjustments of the gland on the stuffing box prevents excessive leakage and keeps the clearances tight for optimal performance. At the same time, optimized piping configurations reduce friction losses, helping both water and energy savings. Combined, these measures significantly reduce reliance on fresh water, which is becoming even more important as operations shift toward processed or seawater supplies.

But first you must maintain

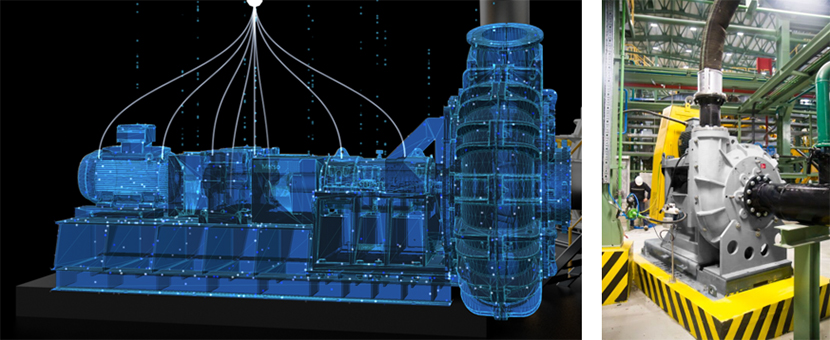

Unplanned downtime wastes both resources and productivity. Without proper monitoring, issues can often become apparent only when a pump or component fails. Leveraging tools such as digital pump monitoring and wear detection systems, operators can anticipate issues before they become costly failures. Real-time insights into vibration, temperature, and seal conditions enable predictive maintenance, which can help to extend wear life and avoid unnecessary shutdowns. By spotting issues early before a failure sets in, the life of liners and wear components can be extended. This helps operators cut down on premature wear and significantly reduces the amount of waste and worn pump components consumed.

Visual and mechanical inspections can also play a role in identifying potential problems. Regularly inspecting glad seals and the stuffing box can also support preventive maintenance and reduce water wastage and extend component life. Looking for signs of heavy wear can also help reduce wastage. In many cases, shifting from rubber liners to metal or vice versa can lead to longer wear life. For example if a customer has been using a rubber lining but is experiencing excessive changeouts, then switching to metal can be an option to extend liner life. It is important to analyze the entire application from the slurry to the pump and liners chosen to uncover the optimal choice.

Pump design is also important to consider. Modular pump designs also simplify part replacement, reducing logistics, material use, and safety risks. Altogether, this leads to greater uptime, lower costs, and a smaller environmental footprint. Some designs allow for easier upgrades if future production conditions or targets change. For example, if production targets are raised beyond a pump’s design limits – an upgrade may make more sense than completely replacing the existing pump. In this way waste is reduced and there may also be additional cost savings that can further strengthen the case for an upgrade.

Pulling it all together

Sustainability in slurry handling isn’t about one pump, liner or component feature – it’s about combining innovations across the full product life cycle. Metso incorporates sustainability metrics into its manufacturing facilities and in every R&D project, ranging from lightweight modular designs that reduce transport impacts to high efficiency motors and drives as well as advanced sealing systems that cut water use. Supported by offerings such as Life Cycle Services, pump inspection programs, and continuous improvement expertise, operators should look to supplier who can act as a trusted partner to meet today’s challenges – higher ore volumes, tougher slurries, and tighter environmental targets. Taking a broader view of the entire circuit is also critical. By addressing pumps, pipelines, and sealing alongside mills, crushers and other equipment in the circuit, operators can unlock a more holistic path to true sustainable performance.

Explore more on sustainable operations options or download the Metso Slurry pumping handbook here Slurry Pump Handbook – Metso

Authors

Diwakar Adur, Product Manager, Metso pumps

David Hengst, Senior Manager, Product Management & PMO, Metso Pumps

Jose Cirujano, Regional Sales Manager, Metso Pumps

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments