Simformotion and Fletcher® Launch High-Reach Scaler Simulator to Advance Operator Safety in Underground Mining

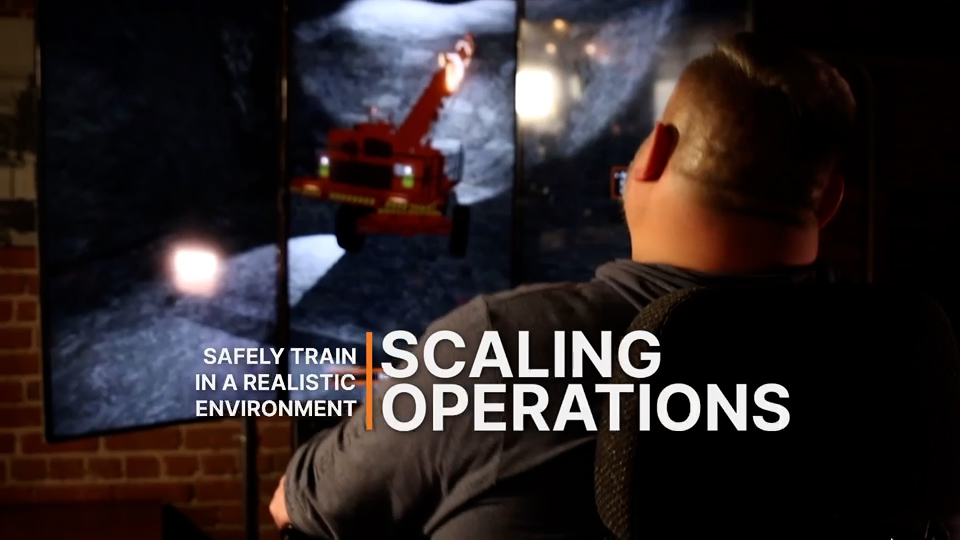

Huntington, WV – In a significant step forward for operator and mine site safety, Simformotion™ LLC and J.H. Fletcher® have announced the release of a next-generation High-Reach Scaler simulator. This cutting-edge solution is designed to equip mining professionals with the skills necessary to safely and efficiently operate underground scaling equipmentwithin the safety of a virtual environment.

Set in a hyper-realistic underground mine simulation, the Fletcher® High-Reach Scaler simulator replicates real-world working conditions with remarkable precision. It combines authentic machine controls, VR-enhanced visuals for depth perception, and motion platforms that help trainees understand crucial tipping points while performing complex maneuvers.

“Mining is evolving, and so must the tools we use,” said Ben Hardman, Vice President of Sales at Fletcher®. “This simulator bridges education and industry, empowering professionals and students alike to lead the way in safer, smarter mining.”

Blended Learning, Real-World Outcomes

The simulator supports a comprehensive set of machine exercises—from conducting pre-operational inspections to proper startup and shutdown procedures, tramming, positioning, and executing accurate scaling techniques. These skills are critical for identifying and removing unstable rock and debris from tunnel roofs and walls, which significantly reduces the risk of falls or collapses before other personnel and machinery enter the area.

Each session is logged using SimU Campus™, a built-in performance tracking and reporting system that delivers actionable insights via a user-friendly dashboard. This data helps both instructors and learners monitor progress and pinpoint areas for improvement.

The system is bundled with SimScholars®, a fully integrated online curriculum. This includes instructor guides, videos, interactive quizzes, and more ideal for classroom settings and remote learning.

“We recognize the urgent need for skilled, safety-conscious operators in today’s mining operations,” said Lara Aaron, CEO of Simformotion. “Our simulator allows companies to build their workforce confidently, knowing that their trainees are gaining hands-on experience without any safety compromise.”

Driving Safety, Productivity, and Cost Efficiency

Simformotion emphasizes that simulation-based remote learning not only enhances safety but also eliminates the need to take expensive equipment out of production for classroom purposes. Operators can practice anytime and anywhere, reducing onboarding times and accelerating readiness for live operation.

Fletcher® Simulators – SIMFORMOTION LLC

About the Companies Behind the Innovation

Simformotion™ LLC is a recognized leader in heavy equipment simulators, offering scalable solutions that support safety, productivity, and continuous education, regardless of weather, location, or equipment availability.

J.H. Fletcher®, a cornerstone in underground mining innovation since 1937, has consistently pushed the boundaries of equipment engineering. Many of its safety features have become industry benchmarks. Fletcher’s commitment to innovation extends through Fletcher Service Inc., which provides comprehensive equipment maintenance and support services.

For more information or to request a demo, contact:

Ike Sturgill

📞 1.304.525.7811

✉️ [email protected]

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments