Smart Crushing Starts Here: Driving Safer, More Efficient Crushing Operations with Data and Design

Redefining Crusher Performance Through Integration

In an industry where uptime is everything, equipment reliability and safety are no longer just operational goals – they’re competitive necessities. That’s where ME Elecmetal steps in.

ME Elecmetal addresses these issues head-on with a holistic approach that combines wear-resistant materials, engineered tooling, and predictive analytics to keep operations safer and more productive.

Their comprehensive approach extends equipment life, enhances maintainability, and reduces risk while ensuring compatibility with existing systems.

“At ME Elecmetal, we’re not just replacing worn parts – we’re reimagining what efficient, intelligent crushing looks like,” said Clint Overman, Senior Director of Business Development – Aggregate. “From liner change-outs to performance optimization, we work with our customers to unlock measurable improvements at every stage.”

Engineered for Seamless, Safe, and Productive Operation

Wear Parts with Purpose

At the core of ME Elecmetal’s offering is a line of precision-engineered crusher wear parts. Built for quick, accurate liner change-outs and manufactured with high-performance alloys, these components are designed to extend service life, reduce downtime, while minimizing operational disruptions.

Safety Tooling: Designed to Protect and Perform

The company doesn’t stop at wear parts. Their custom safety tooling solutions – from ergonomic lifting devices to spider hook systems to crusher nuts, and more – have been developed to safeguard workers during liner replacements and improve overall maintenance efficiency.

“Safety and productivity aren’t mutually exclusive. Our solutions are proof that you can improve both simultaneously,” Overman added.

Redefining Crusher Performance Through Integration

Smart Tools for Smarter Crushing

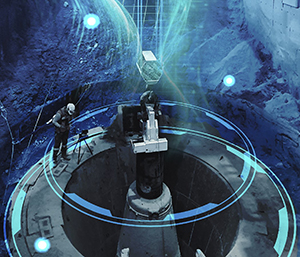

Digitalization is at the heart of ME Elecmetal’s strategy. Some of ME Elecmetal’s advanced Optimization Tools and Services include:

- 3D Laser Scanning: Enables reverse engineering and optimized design by digitally modeling equipment with high accuracy.

- Wear Tracking Reports: Provide actionable insights based on historical operating data, helping clients forecast wear life, plan maintenance, and avoid unscheduled downtime.

- Quick turnaround: Preliminary reports in little as two hours, full reports in two days

- Expert service: Performed by trained professionals using advanced tools.

- QuickScan™ Crusher: ME Elecmetal’s remote-controlled robotic scanning system for primary crushers delivers fast, accurate visuals without the need for manual cleaning – simplifying the scanning process, reducing personnel exposure, and increasing efficiency.

“Our optimization tools and services go beyond traditional support,” added Overman. “Leveraging vast technical expertise and innovative digital solutions, we help you boost equipment performance, predict wear patterns, avoid unscheduled downtime, and make data-driven decisions with confidence.”

Tailored Crushing Optimization with ME FIT

Fully Integrated Technology for Total Optimization

The centerpiece of ME Elecmetal’s approach is its ME FIT Crushing program – a fully integrated initiative designed to address the specific challenges of each mining operation.

At its core, ME FIT Crushing focuses on helping customers achieve their production targets, improve equipment uptime, and enhance long-term operational efficiency. Each engagement is built on a foundation of continuous improvement, driven by close collaboration between ME Elecmetal’s multidisciplinary experts and customer site teams.

Their structured, data-informed methodology aligns directly with customer KPIs. The result is a shift from reactive problem-solving to long-term, measurable improvement – supported by technical expertise and proven digital solutions.

Sustainability and Supply Chain Excellence

Circular Economy Commitment

ME Elecmetal’s solutions don’t just extend wear life – they extend equipment sustainability. The company’s circular economy initiatives include component remanufacturing, scrap recovery, and recyclable liner programs.

Global Reach, Local Support

With ten strategically located state-of-the-art plants across

Chile, the USA, Peru, China, South Africa, Indonesia, and Zambia, and commercial presence in over 40 countries, ME Elecmetal ensures fast delivery, local responsiveness, and consistent quality – no matter where you operate.

Ready to Optimize Your Crushing Operation?

Whether it’s through safer maintenance, data-driven forecasting, or more durable wear materials, ME Elecmetal is helping operations turn downtime into opportunity – and rethinking what’s possible at every stage of the crushing process.

Visit: www.me-elecmetal.com

Call: 480-730-7500

Meet ME Elecmetal at CONEXPO- CON/AGG 2026!

Booth C-30862 | Las Vegas, Nevada

March 3–7, 2026

Join the ME Elecmetal team and explore the latest innovations shaping the future of the aggregate industry.

About ME Elecmetal

ME Elecmetal is a leading global supplier and strategic partner in the mineral processing, aggregate, construction, and recycling industries, renowned for its commitment to innovation and technology. Dedicated to delivering cutting-edge, sustainable solutions, ME Elecmetal consistently exceeds customer expectations worldwide.

With a comprehensive range of products and services – including grinding media, mill liners, crusher liners, and large specialty castings – ME Elecmetal is the preferred partner for crusher operators and mineral processors looking to optimize their operations.

The company operates ten state-of-the-art metallurgical plants strategically located across Chile, the USA, Peru, China, South Africa, Indonesia, and Zambia. With a robust manufacturing capacity exceeding 134,000 tons for foundry products and 600,000 tons for grinding media, the company continues to meet the growing demands of the mining industry.

ME Elecmetal’s commercial presence extends to over 40 countries, solidifying ME Elecmetal’s position as a global leader in delivering innovative solutions to critical sectors around the world.

Learn more about ME Elecmetal’s global footprint and commitment to excellence in integral solutions at

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments