Sustainable protection: A modern take on crusher protectives

Throughout the history of mankind, humans have relied on the various natural resources found on the surface, in the ground and over time, deeper inside the earth. From the industrial revolution until modern times, the advent and advancement of machinery and mining practices has forever changed this landscape. More complex crushing circuits and heavy-duty crushers, for example, have allowed the processing of challenging ores at ever-increasing volumes to meet demand.

Today’s demand for minerals shows little sign of slowing down, but there are global challenges with minerals scarcity, declining ore grades and the need for more sustainable practices to contend with. Perhaps paradoxically, many minerals are also key components for sustainable development and the sustainable energy transition.

Crushing today – the parts that make the whole

In keeping with the pace of development, modern crushers rely on more than just brute force. They can be equipped with intelligent solutions from analyzers to IoT monitoring devices. Percentages truly matter when it comes to large-scale mining operations and small factors can have great impacts on efficiency, end-product quality and sustainability.

Crusher parts too have seen modernization, yet there is more work to do. Working wear parts have perhaps gotten the most attention, with new designs, optimized or tailored chamber solutions, advanced wear scanning and testing as well as a range of alloys that can be chosen to fit the machine and application.

Maximum wear-life solutions, such as Metso MX for cones, can have up to double the lifetime, when compared to standard manganese wear parts. The longer lifetime supports more production time and fewer change-outs. MX for cones also contributes to sustainability with fewer parts manufactured and transported, minimizing materials needed and reducing overall footprint.

However, the focus on working wears has in some cases overshadowed other essential parts such as protective wear parts, which are also pivotal in keeping the crusher running and protecting vital components.

Protecting your most valuable assets

As an analogy, crusher protective wear parts can be seen much like the roof of a house. A poor material choice here would make a big difference in the level of protection for the upkeep, service work needed and peace of mind. Patchwork solutions, some better than others, can function for a period of time but they will inevitably require more attention at some stage.

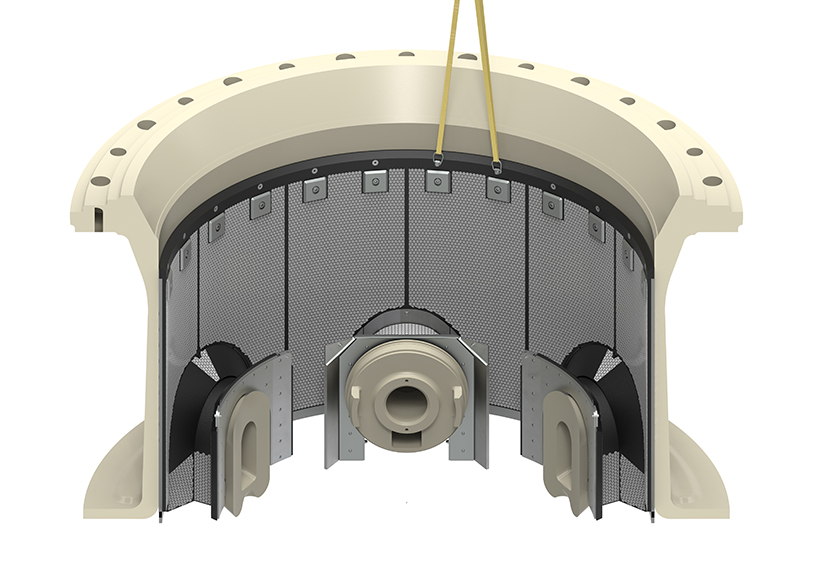

Similarly, protective wear parts function to protect vital parts of the crusher and paying closer attention to them can offer benefits and reduce some risks. While all parts of the machine are important, there are some aspects that can be seen as more critical than others. For example, protecting the mainframe is a key priority to maintain the integrity of the crusher. Other important protective wear parts are countershaft and arm guards.

Sub-standard solutions may lead to protective wears wearing through at inopportune times and in worst cases, material flow potentially penetrating the frame or other structures. In these cases, precious time and resources would then need to be directed into managing the issues created by the failed wears, from maintenance personnel’s attention, lost production time to additional waste created from the short-lasting parts.

Although all machines will need maintenance, predictability is a cornerstone to operational efficiency. Longer lasting protective wear parts can also contribute to better alignment of maintenance cycles with the crushers’ working wears.

Beyond ‘quick fix’ solutions

Today, in many ways, protectives are still an afterthought and managed as ‘it has always been done’. Putting the focus on all parts of the crusher – including protective wears, has never been more important in meeting targets for production, efficiency and a sustainable consideration of the entire lifecycle of parts and products.

Standard options, such as AR steel solutions, are available for less challenging applications that provide a balance between materials, performance and investment. Enhanced AR steel products can provide additional benefits, keeping protectives in good working order and reducing the time needed for shutdowns. These can support more targeted change-outs, so only protectives that are worn out need be changed.

Where durability meets design – next generation protective wears

Development advances in protective wear parts serves to address areas of the crusher where issues are known to occur, by focusing on high-quality materials and engineering for real-life use. For example, in some older crushing models, the countershaft box structure on the oil bowl is a common challenge area where in some extreme duty applications the cast frame can wear out at its narrowest point, exposing the gaskets and shim parts to wear.

This can lead to oil leakage or, in severe cases, crushed material entering the oil bowl contaminating the oil. Very little grit needs to enter the lubrication system and its components before serious wear can occur on bearings, pumps, seals and heat regulators. Newer protective wear products are taking this into account by providing extra coverage to these critical wear surface areas.

An example of a next-generation protective wears product is Metso Poly-Cer. Poly-Cer features a rubber ceramic composite that is designed for maximum wear life. The rubber helps absorb impact shocks, while the ceramics provide exceptional resistance to abrasion.

Poly-Cer protective wears are also engineered to offer full protection of the mainframe while reducing gaps between the liners and they help prevent material buildup and blockages, ensuring smoother material flow. The lifetime improvement is a huge advantage over standard solutions – up to three times and in many cases, significantly beyond. The long wear life also supports more sustainable crushing operations, with less waste and reduced need for new or replacement products to be produced and shipped.

Looking to the future

The future of protective wears centers around ‘design intelligence’, mainly looking for performance enhancements with advanced materials that are fit for purpose. It also focuses on considering materials usage from a circular model or concept, ensuring that production, transportation, use and recycling meet the needs for today’s modern sustainable mining.

Safety is also key, with a focus to make the need for adjustments and welding a thing of the past. Currently, with more advanced solutions like Poly-Cer, lifting lugs and a modular part design supports a ‘plug and play’ model of installation. The development towards making change-outs quicker and reducing risk exposure will make everything as safe and streamlined as possible.

With protective wear parts raising the bar in terms of durability and lifetime, they are gaining in importance when it comes to maintenance planning and optimization. Instead of being overshadowed by working wears, protective wear parts have the opportunity to set a new standard for performance.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments